Digital Product Passport: blockchain technology for regulatory traceability

From 2027 onwards, the European ESPR (Ecodesign for Sustainable Products Regulation – EU 2024/1781) will require the implementation of a Digital Product Passport (DPP) for many categories of goods placed on the European market.

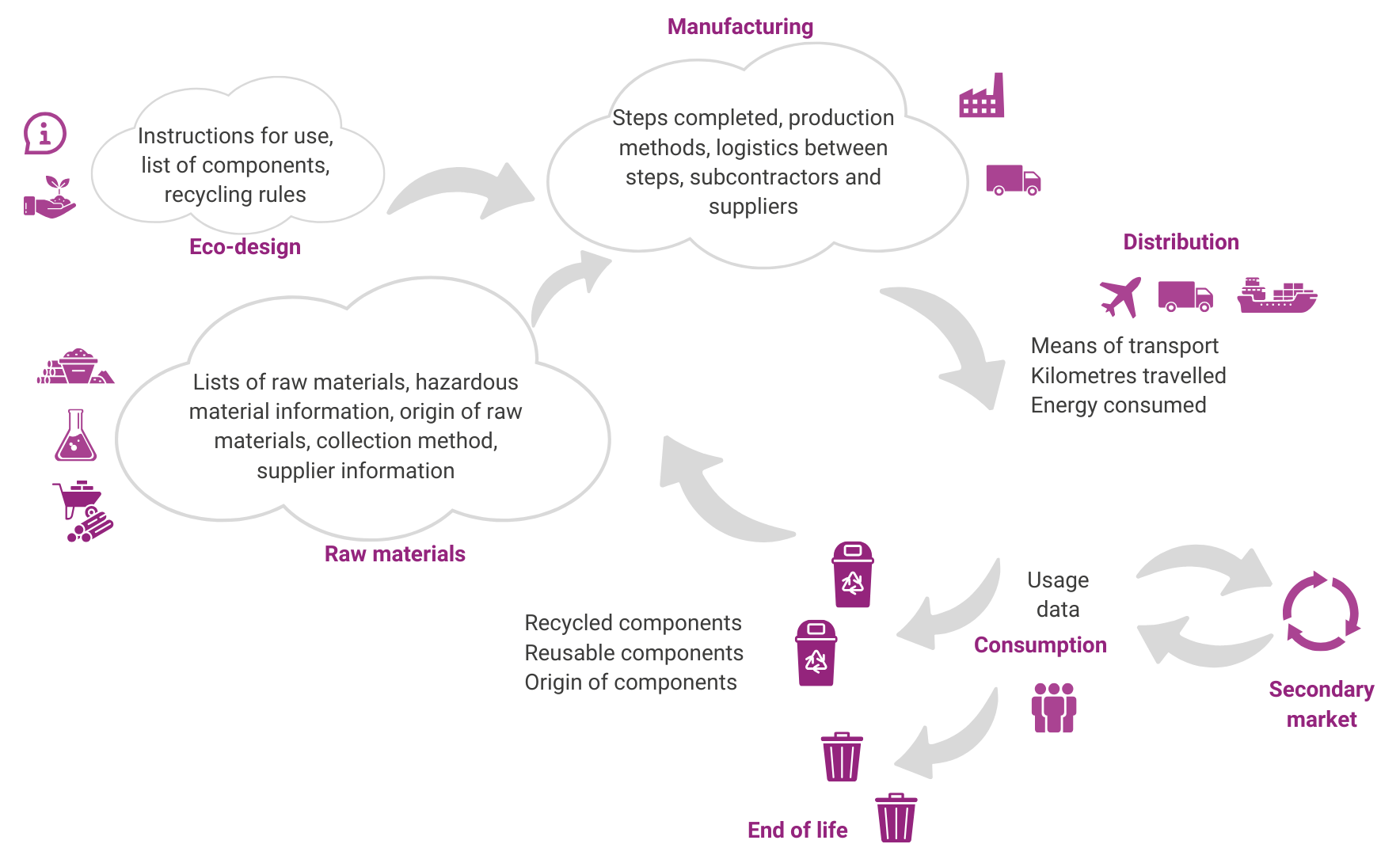

This passport, accessible via QR code or NFC chip, will contain essential data on the product's life cycle: origin of materials, manufacturing process, repairs, environmental performance, recyclability, etc.

To build the DPP for a finished product, data must be collected from all of its tier 1 subcontractors, who must also be asked to compile their own data, and the information provided must be checked for consistency.

For businesses, this new regulatory framework represents a major challenge in terms of data collection, reliability and security. This is where blockchain emerges as a strategic technological solution.

If you are unable to collect data directly from your subcontractors' suppliers, blockchain technology allows you to certify who provided you with the data you use, when, how, and what commitments they signed with you when sending it to you. In a context where the obligation of due diligence across your entire production chain is stronger than ever, blockchain timestamping allows you to prove that your verification procedures have been properly followed.

More and more data to track...

Why blockchain?

Because it guarantees the integrity, immutability and traceability of the data recorded in the passport. Every event in the product's life cycle (manufacturing, transport, maintenance, resale, recycling) can be recorded as time-stamped, tamper-proof evidence that can be verified by all stakeholders.

With blockchain, your customers will be able to easily verify for themselves the accuracy (or at least the origin and non-alteration) of the product data presented, making this technology a guarantee of trust and a commercial advantage.

Traceability is no longer optional!

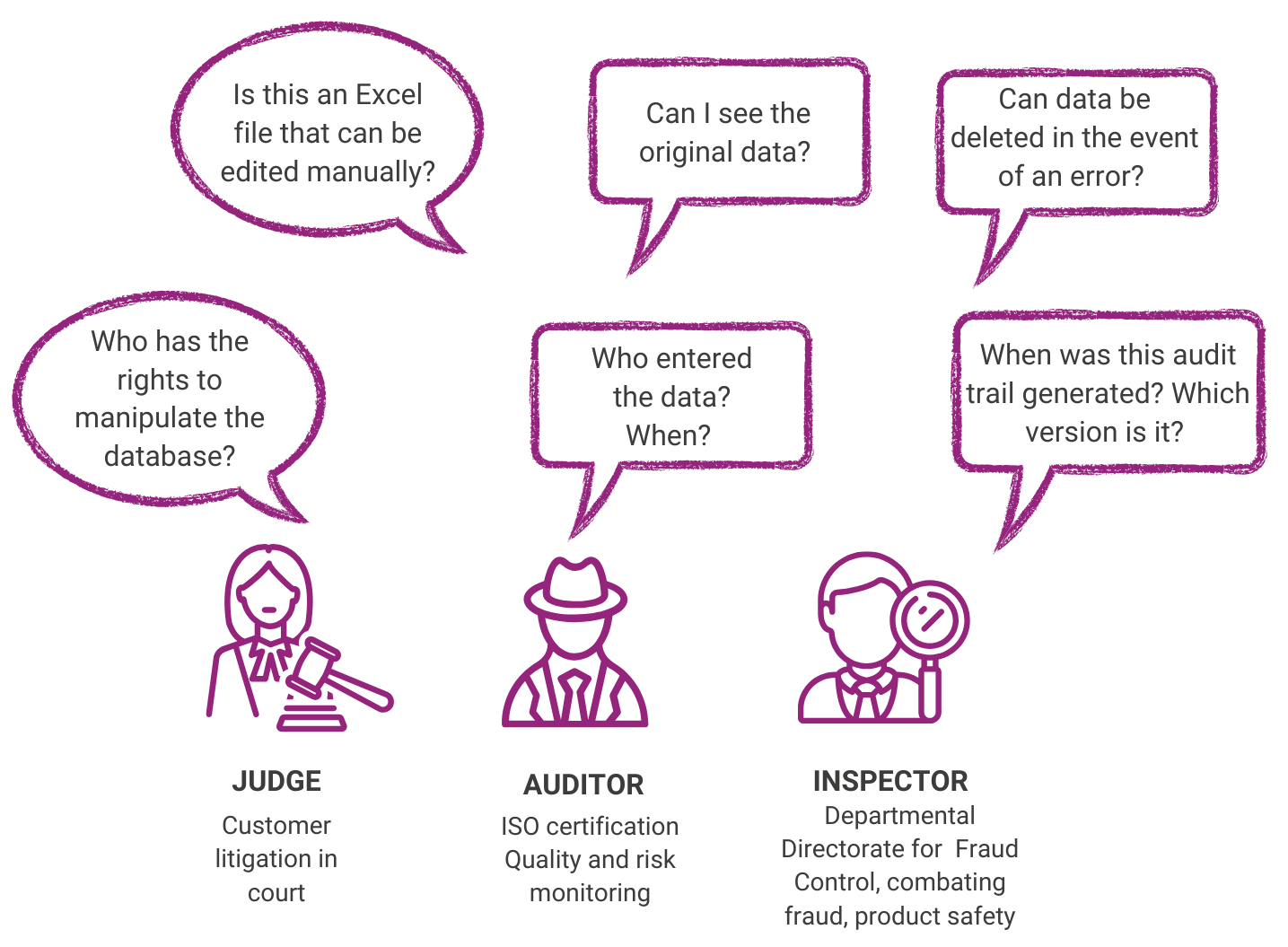

Your auditors and official bodies, such as the Fraud Department or customs authorities, will also be much more likely to validate your declarations if each claim is time-stamped and sourced.

Traceability data can be manipulated

To fully understand the application of blockchain in the context of traceability, we invite you to attend the webinar on this topic hosted by our colleague 👉.

Examples of application:

- A battery manufacturer can certify the origin of the data used on the import of rare metals used.

- A textile distributor can trace the production conditions of a garment.

- A construction company can document the origin of building materials.

- A repairer can record the repairs carried out on a device.

Blockchain also helps prevent document fraud: any attempt to alter a record is detectable, as it breaks the hash chain. This strengthens trust between actors in the value chain and facilitates regulatory audits.

Thanks to its APIs, Tediji integrates easily with production tracking, supplier data collection and storage tools and, overall, makes it possible to trace all the key stages in the production of a product, whether finished or not, and to verify the origin of the data. These same APIs are available to client companies or consumers who may wish to automate the verification of the data sent.

Tediji also allows SAAS solution publishers already present in this market to add an unalterable audit trail to their existing traceability features at low cost.

A European legal framework

The European Commission actively supports the use of blockchain in the context of DPP, notably through the concept of Electronic Registers established in 2024 in the eIDAS 2.0 text, which confirms the admissibility of traceability evidence recorded on a blockchain.

A lever for compliance and competitiveness

By integrating blockchain into their DPP strategy, companies are anticipating regulatory requirements, reducing the risks of non-compliance, and promoting their commitment to sustainability. For lawyers, it is a powerful evidentiary tool, capable of documenting every stage of a product's life cycle with unparalleled reliability.